Problem

A manufacturer of plumbing fixtures was using 10-24 and 8-32 Slotted Round Head Nylon Patch Monel Machine Screws as bibb screws to assemble neoprene washers to brass faucet stems. The costly nylon patch machine screws were losing their locking torque after multiple cycling. Excess torque was required to tighten the neoprene washer to the faucet stem.

A manufacturer of plumbing fixtures was using 10-24 and 8-32 Slotted Round Head Nylon Patch Monel Machine Screws as bibb screws to assemble neoprene washers to brass faucet stems. The costly nylon patch machine screws were losing their locking torque after multiple cycling. Excess torque was required to tighten the neoprene washer to the faucet stem.

Solution

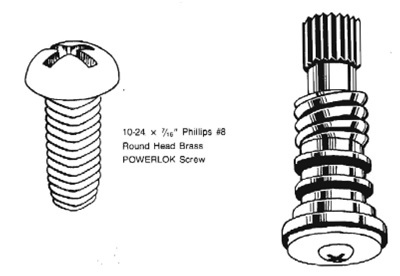

The manufacturer replaced the nylon patch machine screws with POWERLOK® round head brass screws.

Customer Benefit

POWERLOK® screws repeatedly retain their locking action through multiple cycling and exceed IFI locking standards by as much as 400%. POWERLOK®screws also have locking action over the entire length of the engaged shank and eliminated the costly nylon patch application in addition to improving overall product reliability.